WIND

〰️

If you would like to visit the full Skyform Wind Website

〰️

Please Click The Link Below

〰️ If you would like to visit the full Skyform Wind Website 〰️ Please Click The Link Below

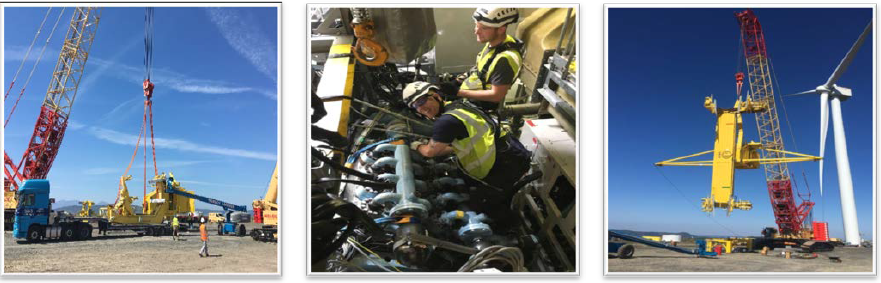

Skyform Wind is part of the Skyform Group a multi-disciplined organisation offering services to the renewable and construction industry. Skyform Wind's engineers are highly skilled and trained to work on both on and offshore windfarm environments.

The company specialises in Statutory Inspection and Maintenance and Repair of Service lifts, Cranes and Turbine Mounted Safety Equipment and has over 20 years of experience in Man Riding Equipment.

Skyform Wind offers a unique ability to perform repairs during inspections which prevents unnecessary downtime and allows for substantial financial savings. Our “One Stop Shop” approach to inspections is completed to international standards and best practice. This service has been successfully carried out at SGRE Beatrice & Hywind, SGRE East Anglia 1 and SSE Griffin.

The “One Stop Shop” service involves a team of technicians performing two Wind Turbine Inspections per day and includes inspections of:

Internal Access Hoist

Climb Assist Systems

Fire Extinguishers

Service Cranes

Eye Bolts

Evacuation Equipment

Fall Arrest Systems

Ladders

Pressure Vessels

Compliance, Inspection & Maintenance

Our full service and repair capabilities are completed to international standards and include experience of working on the following equipment:

Lifts / Towerhoists - Goracon, Skyman, Avanti, Tractel, Powerclimber, Hailo

Cranes - HIAB, Palfinger, HMF, GMH, LIFTRA, Vicinay, Tractel, Yale

Pressure Systems - PRV’s and accumulators including Competent person Written Scheme of Examinations.

Anchor Points, Fall Arrest Systems and Emergency Equipment Pad Eyes. Escape points. Latchways, Miller, Scala/Cabloc, Skylotec. Ladders. Fire Extinguishers.

UK Supply Partners

Skyform Wind are the sole UK Supply Chain Partners of Skyman, Powerclimber and Goracon in the UK and are approved for Service, Repair, Component Refurbishment, Parts Sales.

We have a selection of training lifts Goracon (G Lift and GWB450), Avanti (L & Shark), Powerclimber (Sherpa), Skyman TH250, at our Training Centre in Glasgow. Bespoke training has been developed for our technicians and can also be developed for our customer needs.

We also provide training on the following equipment AAB / Liftket hoists, Davit Arm/ Hoists, HMF Crane, PSSR Systems, General Electrical Awareness

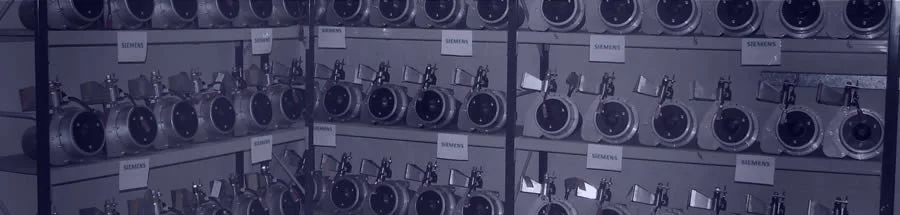

We have a full stockholding of standard parts in our Glasgow Warehouse inclusive of Hoists and Brakes. Our technicians attend site with all common spares and faults are fixed at the scheduled maintenance and inspection to avoid the need for a revisit.

“Skyform is a loyal and reliable business partner of Skyman having worked together for over 20 years. If you were to ask Skyman who is the number 1 name to call in the UK for installing, commissioning, maintaining, inspecting and troubleshooting of our suspended powered access equipment, we would say “Skyform”

CEO Skyman Group

Service Capability

We comply with the Global Wind Turbine Safety Rules and are fully accredited. Our full service and repair capabilities are to international standards and includes:

Man-Riding Lifts/ Tower Hoists

6 Monthly and annual inspection and repair including load test of Skyman, Avanti, Powerclimber, Goracon and Hailo

Service Cranes

Nacelle and Davit cranes including chain blocks. Load tests completed and repair capabilities.

Many manufacturers as HIAB, Palfinger, HMF, GMH, LIFTRA, Tractel, Yale etc.

Chain Hoists

Annual inspections, maintenance and repair for multiple brands including ABB, Liftket, Demag, Goracon etc.

Turbine Mounted Safety Equipment

Anchor Points, Fall Arrest Systems and Emergency Equipment

Blade Access

Bespoke access rig capabilities for onshore and offshore.

Base Grouting, Foundation Waterproofing

Base Grouting and Waterproofing Specialists.

Hydraulic Pressure Systems

Inspection and test requirements performed on PRV’s and accumulators.

Provision of Written Scheme of Examination.

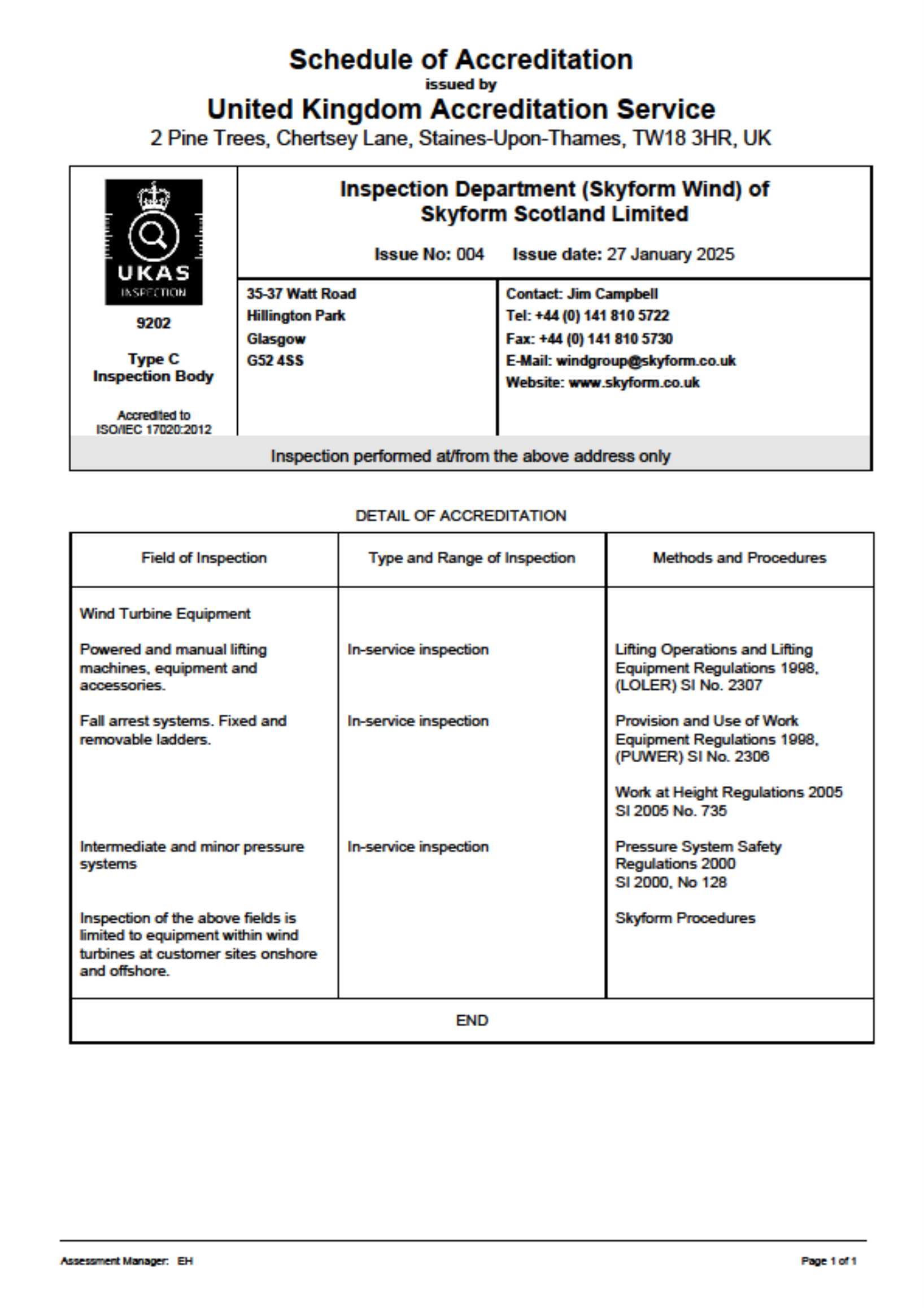

As holders of the ISO 17020:2012 Accreditation, Skyform Wind are a Type C UKAS Registered Inspection Body in the field of

Wind Turbine Equipment

Powered and manual lifting machines, equipment and accessories

Fall Arrest Systems, Fixed and Removable Ladders

Intermediate and Minor Pressure Systems

UKAS Accredited Inspection Body

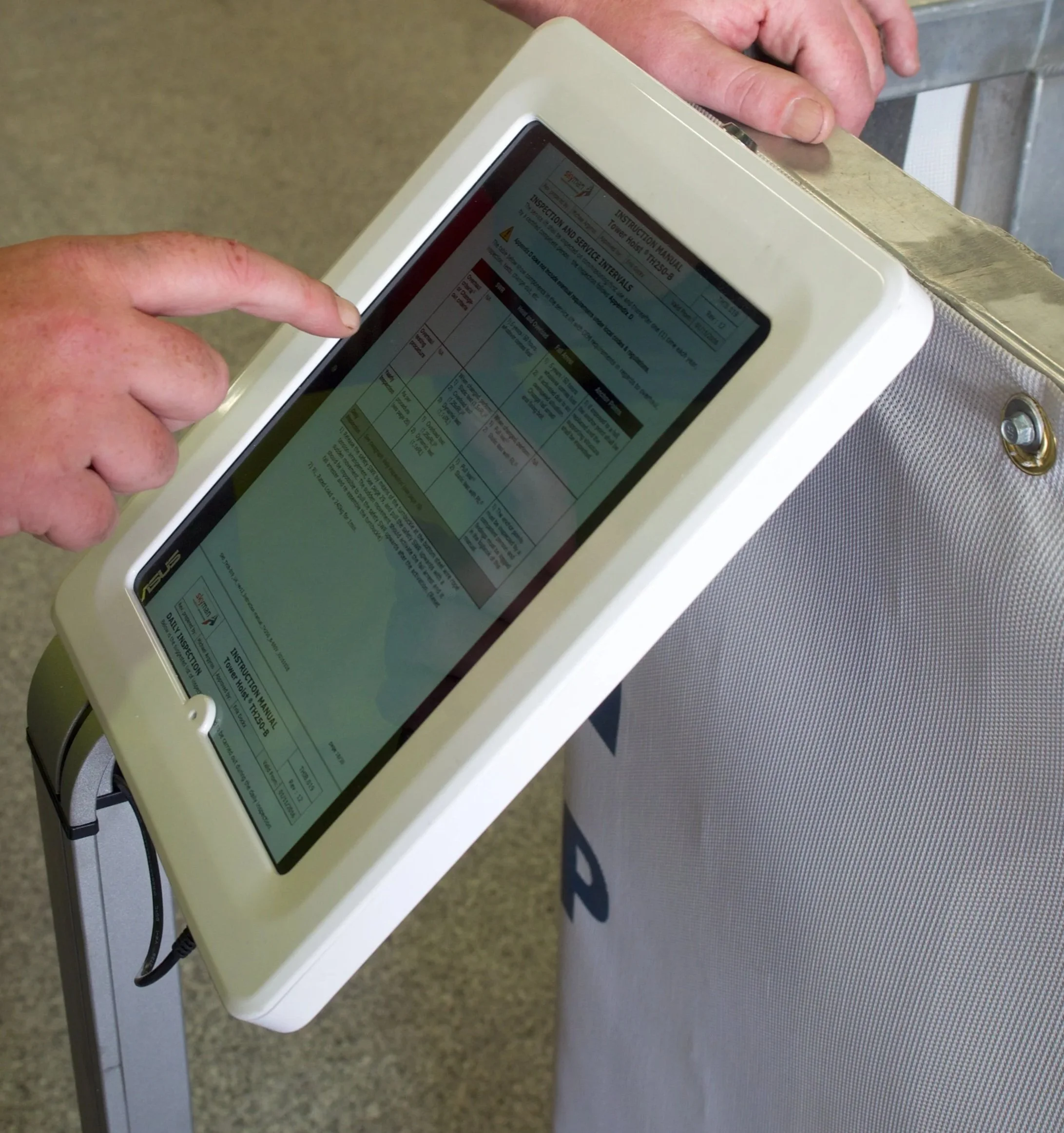

Papertrail Asset Management Software

Skyform have developed a customer focused database which allows improved control of the service management of wind turbine components.

Skyform use Papertrail’s Modular Asset Management Software for Inspection and Servicing records which has been tailored by Skyform Wind to meet our specific company requirements.

The Database contains information on all work completed and future scheduled work, including:

Site location

Site owners

Site service company

Turbine ID and location

Serial numbers of all equipment within the turbine

Engineers who carried out work

Dates of all previous service, complete with paperwork

Notes of any work completed to provide a history

The online database allows our clients access to their information in real time.

Skyform Training Services

Our training covers Power Climber, Skyman, Avanti and Goracon Lifts. At our Training Centre we can tailor build packages to suit the required work on site. Our specialised training centre is situated in Glasgow.

Skyform have provided Training

Siemens Gamesa Renewable Energy (SGRE)

Scottish Power

Natural Power

Global Wind Services

Ørsted

Deutsche Windtechnik

All delegates complete a full written exam and also demonstrate their practical skills on our training lifts before receiving their certificate.

Training Courses can be arranged on the clients premises and Training Packages are available for some courses.

Skyform’s Training Centre in Hillington Park, Glasgow

Service Centre Overhauls

Skyform have a dedicated Service Centre in Glasgow. We can complete full service, overhaul and repair on various types of hoists and safety brakes, including:

Skyman

Goracon

Powerclimber

Skyclimber

Tirak

Tirfor

Scaffor

We can collect hoists from any location across Europe and deliver them fully refurbished to the clients site. As part of this service,

all hoists and safety brakes that leave the service centre will be supplied with a certificate of thorough examination

and a 12 month validity.

Skyman® International TH250 Towerhoist System

Skyform are the leading provider of the Skyman® International TH250 Towerhoist System in the UK and Offshore with over 25 years experience in the Industry. We offer:

Service and inspections on all TH250's including consumable components.

Installation, Commissioning, Service, Inspection and Repair of the System.

Engineers that are all fully trained to access any wind farm across the UK and offshore.

Fully Equipped Workshop to provide repairs to the Hoist and Safety Brake quickly and efficiently, without having to send equipment to Belgium for repair.

Unique database systems for managing all access systems in any wind farm.

Certification of Thorough Examination for all equipment that is serviced or repaired in the workshop.

Skyform Wind’s Work History

A selection of the site locations we have worked - Including Onshore, Offshore and International Locations

Onshore

Achany

Aikengall II

Altwallis

Ardoch over Enoch

Arecleoch Bankend Rig

Bhlaraidh

BAT

BAT II

Bhlaraig

Blackhill

Blacklaw

Blantyre Muir

Broadloch Rig

Calder Water

Calliachar

Carcan

Carland Cross

Carno II

Carraig Gheal

Causeymire

Clochnahill

Clyde

Cruach Mhor

Crystal Rig I

Crystal Rig II

Crystal Rig III

Dersalloch

Drumderg

Ewe Hill I

Eew Hill II

Farr

Forss I

Forss II

Onshore

Glens of Foudland

Gordonbush

Griffin

Hagshaw Hill

Harestanes

Hill of Towie

Hunterston

Keadby

Kilgalioch

Knabs Ridge

Lochluichart

Long Hill

Maerdy

Mid Hill

Millourhill

Minsca

Moel Maelogen 1

Moel Maelogen 2

Moel Maelogen 3

Mynydd Y Bewts

Neart Na Gaoithe

Pauls Hill

Port of Tilbury

Rothes I

Rothes II

Royal Tarlair

South Nittanshead

Stronlairg

Toddleburn

Torrance

Wetherhill

Whitelee

Wathegar 2

Offshore

Barrow

Beatrice

Burbo Bank

Dudgeon

Eyemouth

East Anglia

Greater Gabbard

Gunfleet Sands

Gynt Y Mor

Hornsea I

Hornsea II

Hywind

LID

Lincs

London Array

Lynmouth

Rhyl

West of Duddon Sands

Westermost Rough

International

Amrumbank

Björkhöjden

Borkum Riffgrund

Coomacheo

Godewind II

Godewind I

Heron

Meentycat

Meerwind

Mörttjärnberget Ögonfägnaden

Stamåsen

Scily Alia Sclafani

Tenerife Bermejo

Tenerife Vera de Abote

Veja Mate

Skyform Wind Case Studies & Work Scopes

Beatrice Offshore Windfarm, Scotland (SSE)

Skyform were appointed to carry out Statutory Examinations Annual Service & Maintenance of

88 7MW offshore Turbines including Avanti Service lifts DEMAG Crane

Turbine Mounted Safety Equipment

PSSR WSE and Inspections Towerhoists and HMF Cranes and Lifket Chainhoists

Greater Gabbard Offshore Windfarm, Lowestoft, England (SSE)

Skyform are holders of an ongoing framework for assistance with Lift repairs and resolving technical issues that the current one stop shop contactor doesn’t have the technical ability to resolve. We also carried out Statutory examinations in turbine and on TP on this site from 2010 - 2015 for SGRE.

Clyde Windfarm Scotland (SSE)

This project includes Annual Service & Maintenance of 245 Avanti Towerhoists and HMF Cranes and Lifket Chainhoists, Adhoc Repair assistance in conjunction with Statutory Inspections.

East Anglia One, Lowestoft, England (Scottish Power/ Iberdrola)

Skyform were contracted to complete work on over 100 7MW Turbines. The scope included Full Statutory Inspection, service and Maintenance of Goracon Lifts, Demag Crane, Turbine mounted safety Systems, PSSR WSE and Inspections, PPE Inspections, PAT Testing, Lifting Gear and Tackle Inspections

London Array, Ramsgate, England (London Array Ltd)

Skyform were responsible for the supply of parts and adhoc specialist services in relation to Skyman Lifts

Hywind

Skyform completed WTG Service and Inspection, Avanti Lift, Demag Hoist, TMSE Inspections – 5 5 Floating Turbines

Hornsea 1 & 2 Windfarms

Skyform completed the following work scope at Hornsea 1 and 2 Windfarms for SGRE and Orsted:

Hornsea 1 – SGRE – WTG Inspection, Goracon Lift , Demag Hoist, TMSE Inspections xnr Turbines

Hornsea 1 – Orsted – TP & Deck Crane Service and Inspection, Avanti Lift, Demag Hoist, TMSE Inspections x number turbines

Hornsea 2 - WTG Inspection, Goracon Lift, Vicinay Hoist, TMSE Inspections X number turbines

SGRE - Onshore and Offshore Statutory Inspection Framework for the Service, Maintenance and Repair of Various Windfarms, On and Offshore UK Wide (Siemens Gamesa Renewable Energy, Scottish Power, SSE)

Skyform have an ongoing framework contract covering around 800 windturbines on and offshore. Stat Inspections, Service Maintainance and repair of multiple brands of Lift, Hoist, TMSE, TP's Davits, PSSR Systems

NNG Pre Assembly

This project includes WTG Inspection, Goracon Lift, Demag Hoist, TMSE Inspections – 54 Turbines

Sea Angel Wind Turbine Decommissioning

Skyform Group were appointed by Mitsubishi Heavy Industries Europe Ltd as the Principal Contractor on the Sea Angel decommissioning project in West Kilbride. The substantial task started in June 2018 after several months of project preparation.

The 7 Mega Watt Prototype Wind Turbine was erected in 2015 and stood at 193 meters. It had a rotor diameter of 167 meters – which made it nearly as wide as it was tall.

The Sea Angel was built specifically for research and development. It was one of two turbines installed at the Hunterston Onshore Test Facility. Skyform were responsible for managing the decommissioning, dismantling and disposal of the turbine.

A significant challenge faced by Skyform has been careful planning to accommodate the vast size and scale of the turbine components – it took 3 weeks to finish building the crane. Before dismantling work could begin, Skyform removed 8000 litres of oil which was recycled by a local contractor. The dismantling of the turbine included degassing numerous accumulators prior to removal.

The blades were removed and lowered to the ground individually using the Blade Dragon Lifting Yoke. Each blade weighed 42 tonnes, which is more than the weight of 3 double decker buses.

Jim Campbell, Managing Director said

“Skyform are pleased to have been part of the Sea Angel decommissioning project. The turbine has been a landmark in the local area and a familiar sight to many. I would like to acknowledge and give thanks to everyone that contributed to the successful delivery. The project was concluded ahead of schedule and without injury”